How Does Sieving Equipment Work?

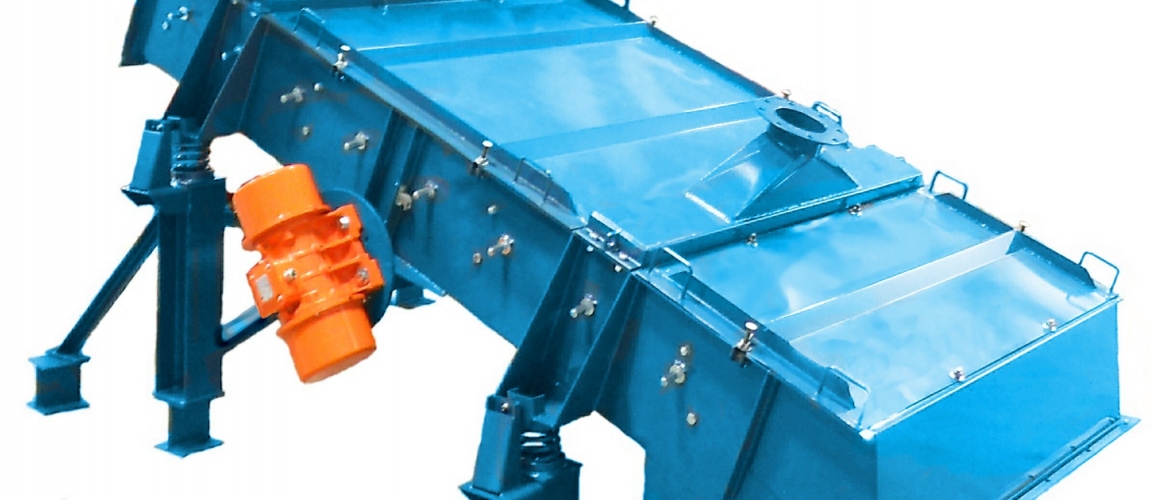

Industrial mechanical sieves are essentially meshes which vibrate, powered by electricity. The size of the mesh and the power of the vibration will differ. Some machines use several different meshes to grade several sizes of material, or are tilted at specific angles. All perform the function of dividing particles of material up by size.

Screening Dry Materials

There are a range of industries where screening equipment is used to separate powders or other dry particles. In the food industry, for example, sorting equipment is used to separate particles of flour, sugar, tea. coffee, salt, spices and many more substances. The equipment sorts food with accuracy and allows for extremely high levels of hygiene, as no other material can accidentally be introduced during the sorting process from the environment or from workers’ hands.

On the other end of the spectrum are sieving units used on building sites to sort material from debris for recycling. These units are hygienic for the opposite reasons – instead of preventing contamination of the materials, they prevent contamination by the materials. Dirty or dangerous substances which might cause injury when sorted by hand can be quickly and safely sorted using this simple industrial process.

Other industries also use screening equipment to sort powders and particles by size. Metal powders such as gold, silver, stainless steel and zinc oxide are sorted by sieving, so are industrial materials such as concrete, ingredients for glass, paint powder pigments and silicates.

Machines used in dry screening are often enclosed to prevent dust or gas caused by the screening process to escape. Many machines are self-cleaning, with simple mechanisms such as steel balls included to prevent powder from clogging the mesh.

Screening Wet Materials

Wet materials also need to be screened but the challenges are different. Sometimes the material is a liquid, sometimes it is particles contained in a slurry, sometimes it is wet or sticky substances. In the food industry, for example. Mechanical sieving equipment is used in dairy production and with fruit juices, liquid chocolate and micro algae. Here, hygiene is again of paramount importance.

Other industries also use screening machinery with wet material. In the coal industry, coal slurry is screened to separate coal fines from the ash content. Liquid fertiliser is screened, as are slurries of glaze, enamel or silica. Very fine meshes are used in these processes, and the machines involved are often multi-screen and multi-frequency. Wet screening has been developed considerably over the past 25 years and now substances which were thought impossible to screen are sorted mechanically every day.

Both wet and dry screening have certain benefits in common. Both types of machine perform a task which could be dirty repetitive or time-consuming for employees to perform by hand. They perform these processes very quickly, accurately and with a high degree of safety, needing little supervision. This means that industrial screening allows for considerable improvements in employee safety, in hygiene and in productivity. when used in a variety of settings.

Comments are closed.