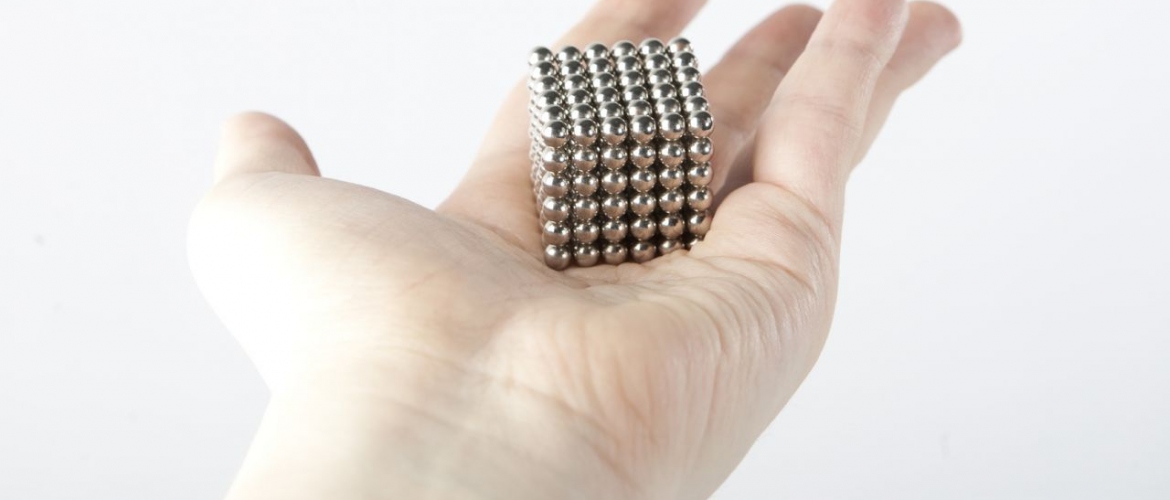

Neodymium magnets are also known as rare earth magnets. They are the most powerful ones compared to any other types of magnets on this earth. They are so powerful that they can lift 1300 times more weight than their own weights. Due to their powerful composition, neodymium magnets are used in a number of applications. These include both industrial and regular ones.

What is best about neodymium magnets is that they are very powerful in nature. They are used for many purposes, and they are not that expensive. The name ‘rare earth’ has been given to these magnets, because they are made of rarest elements. They can be mined from several ores. They are paramagnetic in nature meaning that they can be magnetized very easily.

Composition of Neodymium Magnets

These magnets are composed of iron and boron and are represented as Nd2Fe14B. They appear to be like a single metal, but actually these magnets are metal alloy – bond of three metals. The composition of neodymium magnets includes high-quality metals, which make these magnets very strong in nature.

Plating of Neodymium Magnets

Due to the fact that these magnets are made of three types of metals neodymium, boron and iron, they have a way of reacting. Because of the composition of iron, these magnets will rust, when exposed to water. In order to prevent these magnets from corrosion, you can coat or plate them. There are many materials you can use for coating. Nickel is one of the most common materials used for coating on neodymium materials.

If you need the magnet to be very resistant to corrosion, then you can do multilayer coatings on it. You can use nickel for the first coating, copper for second coating and finally nickel again for the third and final coating. With three coatings, neodymium magnets can be very strong and durable.

How these Magnets are Manufactured?

Neodymium magnets are manufactured by first melting down the iron boron alloy and then this alloy is crushed into powder form. This powder is then aligned to give it a shape of magnet. They are then heated and pressed to give them a solid look. Once molded in a solid brick-like structure, they can be cut into the shape you want to.

Properties of Neodymium Magnets

These magnets are very powerful due to their strength between N24 and N55. N55 is the strongest structure, but has a very low working temperature. The maximum temperature neodymium magnets can tolerate is up to 200 degrees C. Beyond this temperature, these magnets start to melt.

What are these Magnets used for?

There are multiple usages of these magnets. Due to their high strength and efficiency, these magnets are used in electric motors too. They are also used in speakers, toys, computers and electronics items. Aircraft manuafcturing companies employ these magnets while designing certain parts.

The growing demand for this magnet has also enhanced its applications. You can visit any website offering neodymium magnets for sale, to know whether the magnet can be employed in manufacturing any particular part or not.

Comments are closed.