From industrial machines to the applications in the household appliances that we use every day, the use of o-rings is indispensable, literally. These o-ring seals come in a different variety of forms and sizes and each type of ring have its own use and purpose. It is basically a circular ring that is made of rubber and it is used as a seal, a connection, between different parts in the machines. While there are different types of o-rings available, the Viton o-rings are one of the most popular types of rubber sealing rings.

These rings have known to be the simplest and the most reliable seals. It is also extremely versatile and it can be used for both static and dynamic applications in a wide variety of industries. These rings are usually made of different flexible and elastic materials like silicone, neoprene, fluorocarbon, polyurethane and nitrile rubber. The flexible design feature of these seals implies that it can retain its original shape even after it is exposed to high levels of pressure. These rubber seals are commonly used in the mechanical and manufacturing industries. This is because they prove to be comparatively more cost-efficient to the manufacturers or the industrial owners. Not to mention, these seals are best type of seals for everyday usage items like automobile engines.

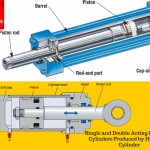

A connecting device, which looks very similar to a pipe designed with the housing or a groove to ensure that the rings are firmly affixed in its place. Once when you place the ring in its groove, it helps to create a strong and reliable seal and prevent leakage between the objects that the seal is connected to. If you are using the seal for static applications, it may be used for connection between the regular piping. Whereas, if you are using the seal in dynamic applications, the connection is more likely to have a hydraulic cylinder.

While, the Viton o-rings are known to have the ability to resist the daily wear and tear, it is best advised that you keep the rings sufficiently lubricated. This would not only help you in increasing the lifespan of the rings but also help you in maintaining the performance of the machinery to its optimum capacity. The key to lubrication though is to use the right kind of lubricant as well as use the right technique for lubrication. This would help you prevent the deterioration and the wear and tear of the rubber that takes place over a period.

One of the key aspects of using a rubber sealing rings is to ensure that the seals are mounted correctly. A seal that is well mounted has the capacity to endure a significant amount of pressure and prevent loss due to leaks in the machine. Depending on the material that is used for making the o-ring, certain types of rings have better durability than others. For example, a nitrile rubber ring is ideal for applications where the seal would be exposed to hydraulic fuels, solvents and oils. Whereas the metallic rings would be better for using in an application where the seal is exposed to high temperature.

Know your exact purpose and the application in which you are going to use the seal and choose the best one accordingly.

Comments are closed.